AIMSCO eChecksheetsTM

AIMSCO eChecksheets™ (eCS™) provide work instructions, images, and data capture to guide worker actions and inputs.

AIMSCO’s clients can quickly build and deploy eCS to production. Moreover, existing eCS can be rapidly enhanced to deploy improved production and quality initiatives. Examples of eCS in production by AIMSCO clients for production, quality and plant management are shown below.

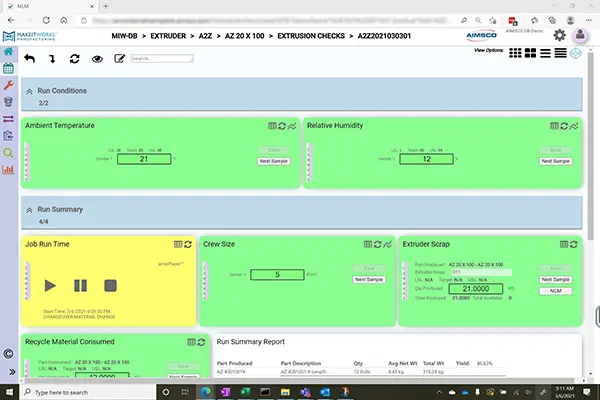

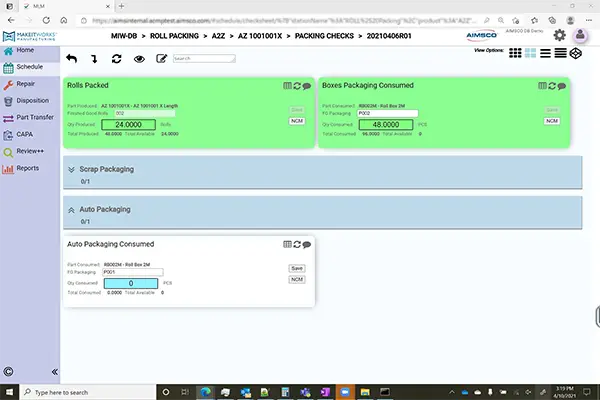

Production Operations

Purpose-built eCI™ and supporting interfaces enable eCS deployments covering a broad range of modern industrial operations.

- Track and Trace: Manage inventory, movement, batching, split and transfer of produced, consumed, supplied and quarantine parts with flexible tracking options.

- NCM / Disposition: Collect non-conforming material details at multiple levels, then review and disposition with a customizable role-driven workflow.

- OEE: Capture of stratified throughput, quality and downtime give interactive insight to asset effectiveness and product performance.

- Process Monitoring: Real-time acquisition, setpoint vs actuals visualization and event visibility yield deep cause-and-effect relationships and drive ML-based optimization.

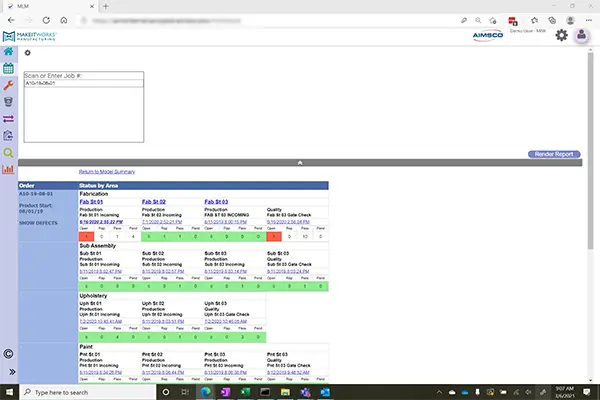

Quality Operations

Diverse features for quality data collection and role-driven interfaces for repair, rework, and sign-off workflows power eCS to assure quality throughout the factory.

- In-process Quality Gates / Checks: Ensure critical-to-quality checks are performed at key processes, leveraging built-in SPC tools to highlight trends in real-time.

- Repair / Rework Management: Assign causes for later analysis and capture images and attachments for further detail.

- Visual Quality Heat Maps: Identify location-based hot spots with AIMSCO exclusive IQMap to solve problems quickly.

- Warehouse / Receiving Inspection: Easily gather logistics quality data to identify transportation or handling issues.

- Supplier Quality / Scorecards: Track performance and highlight concerns across a variety of user-defined dimensions.

- Warranty: Identify recurring issues and weak links in the supply and distribution chain by detailed returns analysis.

Site Operations

Manage routine activities at different locations and assets at your site based on flexible sample or time-based schedules.

- Setup / Work Instructions: Supplement data collection and inspection with online work instructions including rich text, links and embedded images / video.

- Maintenance: With schedule or runs-based triggers, with supplemental data collection and work instructions ensure smooth site operation.

- Safety / workplace / 5S audits: Assure compliance with eCS to review best practices for workplace organization.

- Time & Labor Tracking: Record start, stop, crew size and individual operators against orders.